The Program™

The Program™ is a tried and true set of procedures adapted for each partner by maximizing the efficiency with which fiber waste is recycled by arranging its transport from plant to paper mill in a measurable, defined way on a daily basis.

Goals and Objectives

Enhanced Revenue

Landfill Diversion

Reduced Trash Hauling Expenses

Increased Work Flow Efficiency

The Program™ Case Studies

How does The Program™ work?

Plant Waste Audit to identify and improve current plant practices

Customized Action Plan to maximize revenue on all grades of recyclable material

Educate Plant Personnel on new procedures to share responsibility

Identify and facilitate new equipment solutions

Locate a destination for all your scrap at maximum value

Meeting and Exceeding Your Goals

We create sustainable and teachable processes which maximize potential revenue within the market for all grades of recyclable paper, plastic, aluminum and film because products deserve it.

We achieve a high level of efficiency by reducing landfill waste pickup frequency thus lessening the carbon footprint.

We explore and define the potential to monetize every working square foot of plant.

Your Plant, Your Solution

We educate plant personnel to manage their individual areas procedurally.

We share responsibility for implementing The Program™ so all personnel have ownership in its success.

You will have total control of your plant recyclables and waste train.

Core Approach & Procedures

“Touch it once, touch it right”

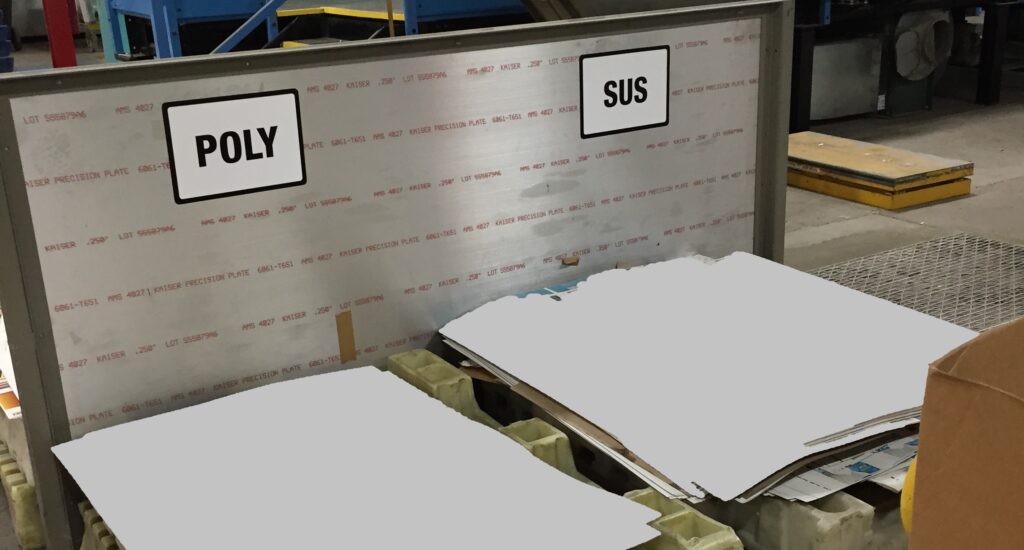

Clear Identification, permanent placement

Comprehensive plant waste audit

Examine waste train

Superior account management and customer service established from day one

Full accountability

The Program™ Plant Waste Audit

WHAT IS A WASTE AUDIT?

A formal, structured process designed to identify current waste practices and how they can be improved.

SPECIFIC OBJECTIVES

We determine the composition and quantities of waste being generated.

We collect baseline data to measure the effectiveness of waste minimization procedures.

We measure the effectiveness of existing waste management systems.

We identify opportunities for improving waste management systems and strategies.

ULTIMATE GOAL

To determine a defined path to a more efficient and effective plant with reduced waste management costs, maximized scrap revenue, and an improved command over deployment of limited resources.

The Program™ Customized Action Plan

- We produce a workflow chart that tracks the efficient movement of scrap through the facility.

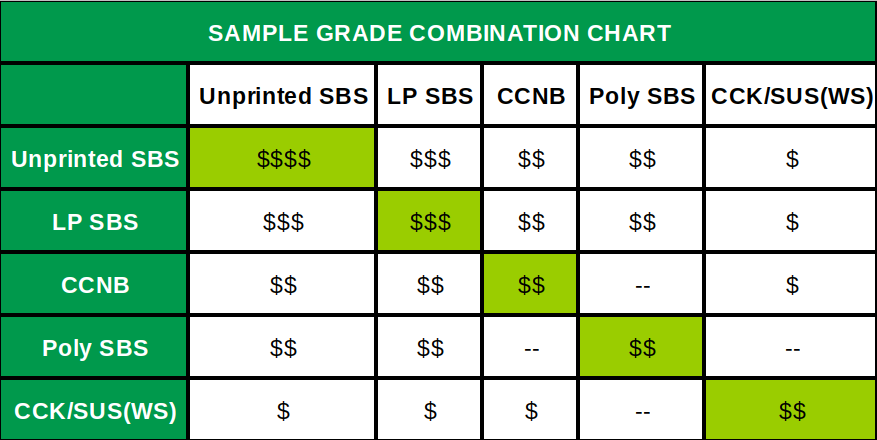

- We standardize your recycling grades to ensure maximum deserved value for all materials.

- We recommend plant upgrades including receptacles, equipment, and improved collection techniques.

- We create opportunities for lower labor costs and the highest deserved value for scrap.

- We identify and facilitate ideal equipment solutions to fit your needs.

“Our job is to listen to paper mills to learn what they want and give it to them as consistently as possible at the highest value back to our suppliers.”

Stuart Lurie, Co-Founder and Board Chair

Marketing and Logistics

We find a destination for all scrap through our worldwide, long-term relationships with consumers of recyclable material.

We create an environment of clear identification, consistent segregation, and physical integrity which results in premium pricing over the long term.

The Program™ Controls, Monitoring and Results

Through real-time reporting and strategic communication, The Program™ offers your plant administration the ability to track and report results.

Efficient, sustained, measurable and repeatable procedures are defined and implemented for recycling and disposing waste.

Less comingling of different fibers and materials that result in increased supplier revenue.

The Program™ Benefits

Each facility will receive maximum potential revenue within the market because the product will deserve it.

All scrap fiber is upgraded to its highest level of value and all grades will be picked up in a timely fashion.

Premium quality scrap collected and generated through efficient procedures on a consistent basis will result in maximum revenue.

The Program™ is certain to increase the landfill diversion percentage of Wilmington Paper’s partners.

Wilmington Paper forms a partnership with each of its facilities participating in The Program™, functioning as an in-house recycling manager operating on their behalf.

The responsibility for implementing The Program™ is shared between the partner facility and Wilmington Paper.

Wilmington Paper keeps its partners aware of current and future market conditions, continually adapting The Program™ to capitalize on any and all opportunities.

All grades of recyclable paper, plastic, aluminum and film are dealt with, not just the “glamour grades.”

All problems can be identified and reacted to with urgency. Nothing falls through the cracks.

Wilmington Paper keeps their partners informed of every aspect of The Program™ so that its partners are in total control of their recyclable program.